| Processes |

|

|

| Core Processes: |

|

| |

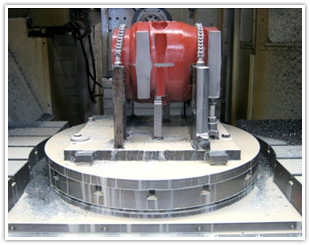

Machining

- Horizontal Machining Center

- Vertical Machining Center

- Turning Center

|

|

|

|

| |

Foundry Management

We are capable to cast the following alloys:

- Gray iron

- Ductile iron

- NI resist

- Carbon Steel

- Stainless alloys

- Aluminum

- Bronze

|

|

|

|

| |

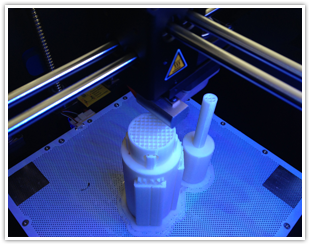

Pattern

We have over 30 years experience in Pattern making.

The materials that we can use are:

- Wood

- Aluminum

- Iron

- Plastic Resins

|

|

|

| |

|

| |

|

Additive manufacturing

|

|

|

|

|

|

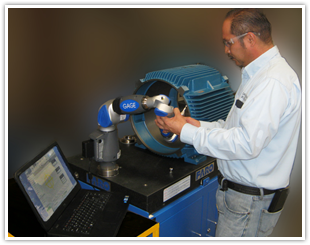

Metrology

We have a metrology lab. equipped with coordinate measuring machines and We also count with controlled areas for critical part inspection to be able to achive 0 PPM´s.

Our staff is trained to interpret drawings according to American and European standards.

|

|

|

|

| |

|

Machining floor SPC

analysis and GD&T,

capable |

|

|

| |

|

| |

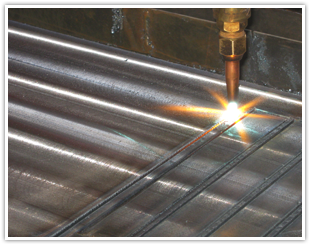

CNC Cutting

|

|

|

| |

| Secondary Operations: |

|

| |

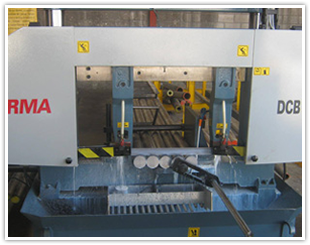

Cutting

We can saw cut from ½ "to 10" in solid, tubbing round, square or rectangular.

|

|

|

|

| |

Shot Blast and

Sand Blast

Moreover, we have equipment for metal cleaning as Shot Blast and Sand Blast. |

|

|

|

| |

Powder Coating

We have a powder coating area and we are able to offer different specifications according to our customers needs. |

|

|

| |

|

| |

Covering Pieces

Within the secondary processes we offer galvanized and phosphatized and stripping of metal parts.

|

|

|

|

| |

Parts Washer

|

|

|

|

| |

|

Assembly Capable |

|

|